Quality

Quality

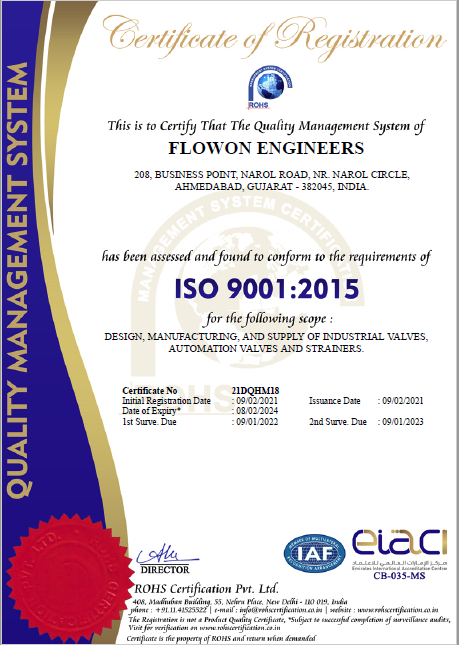

In order to meet the International Quality standards of the products, FLOWON Engineers is ISO 9001:2015 Certified company as Quality Management System, accredited by IAF and EIACL for the scope of DESIGN, Manufacturing and Supply of Industrial Valves, Automation Valves and Strainers. ISO accreditation ensures the high quality services performed by individual experienced personnel to meet the customer requirement with safety company operation which in turn increases the profitability of the organization.

FLOWON is equipped with in-house testing and inspection department which are performed by highly qualified NDT Level-II Quality Engineer in order to maintain the quality of our products. A detailed Quality Assurance Plan (QAP) and General Arrangement Drawing (GAD) is submitted to the Client for the approval prior to starting of production. Provision of Third Party Inspection (TPI) like SGS, Intertek, BVQI, TUV etc. After inspection, Detailed Inspection report is submitted by our quality engineer to our client.

In Order to ensure that our products comply with the international Standards, FLOWON is equipped with complete range of testing equipment for monitoring the quality control. Some of the Equipment includes:

Stage Wise Dimension Check: Using the proper tools like Vernier Caliper, Micrometer, Bore gauge, Wall thickness caliper etc, Our Quality Engineer inspects each and every incoming Raw material (Casting ,Forging etc), Semifinished (machined parts) and finished material (Valve dimensions) to ensure the quality as per applicable valve standards.

Radiography Test : We have inhouse facility for Radiography film evaluation ranging from 0.1” to 2.5” wall thickness to verify the quality of casting. Flaws and cracks are detected easily if present. For evaluating Radiography films, complete range of comparators are available in our lab.

PMI Test: As we are dealing with Different superior grade alloy steel material, we have our own PMI machine which provides fast , easy and accurate chemical analysis of different austenitic alloy steel material compositions.

Hardness Test : FLOWON is equipped with hardness tester to determine the hardness of material. We uses different hardness testing techniques like Brinell hardness testing, Vickers hardness testing and Rockwell hardness test to comply with the standards.

Ultrasonic Test : For small casting and forging where radiography cannot be done, Ultrasonic testing is carried out to detect flaws and cracks in the casting and forgings. We also utilize this test for measuring the wall thickness of castings and forgings.

Fugitive Emission Test : Fugitive emission test is carried out by inert gas( Methane or Helium) to detect the small leakage from valve which are not detected in hydrotest and air test. We have inhouse provision for fugitive emission test as per customer requirement.