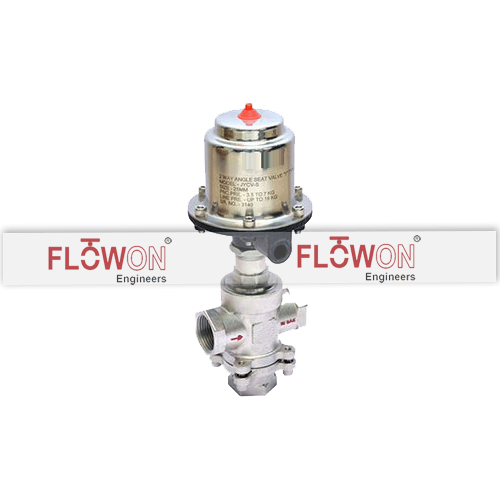

3- Way Mixing-Diverting Control Valve

3-Way Mixing-Diverting Control Valve

‘FLOWON’ Mixing Diverting Control Valve is basically designed for controlling the fluid flow maintaining the temperature of outlet fluid from mutually 3 directional ports. In Mixing Application, where the desired temperature of fluid is required, the actuator will equally proportionate the hot and cold fluid coming from 2 inlet ports and deliver it to the outlet port, thus achieving desired temperature. Same case happen when two different fluids are mixed to achieve third one. Where as in Diverting Application, where the fluid is supplied from one section of valve to another, the actuator will automatically divert the inlet flow to desired outlet port depending on fluid temperature. For Air/Inert gas applications, it is recommended to use moisture separator for dry inlet of air.

SALIENT FEATURES

- Fully control of fluid with minimal pressure loss

- Smaller size available in Investment casting which makes it light weight and cost effective.

- ‘FLOWON’ Mixing-Diverting Valves comes with Class-4 leakage tight shutoff.

- Heavy duty valve able to operate with the range of 375-670 cycles / hr.

- Actuator is made up of Stainless steel unlike plastic to withstand the Vibration caused due to operation of valve.

- Maximum working temperature of 230 ⁰C can be achieved using VITON seat.

TECHNICAL SPECIFICATIONS & PRODUCT RANGE

- Actuator: S.S-304 Pressure Die cast

- BODY: ASTM A 351 GR. CF8 / CF8M / CF3M (On Request)

- Working Parts: S.S-304 / S.S-316 / S.S-316L.

- Seat: PTFE, CFT.

- Temperature: Up to 180⁰ C (Higher temperature on request)

- Pressure Rating: 21 bar maximum

- Leakage: Tight Shutoff

- End Connection: Screwed End (BSPF, NPTF) & Flanged End

- Size range: ½” to 2”.