Pneumatic Actuated Ball Valve

Pneumatic Actuated Ball Valve

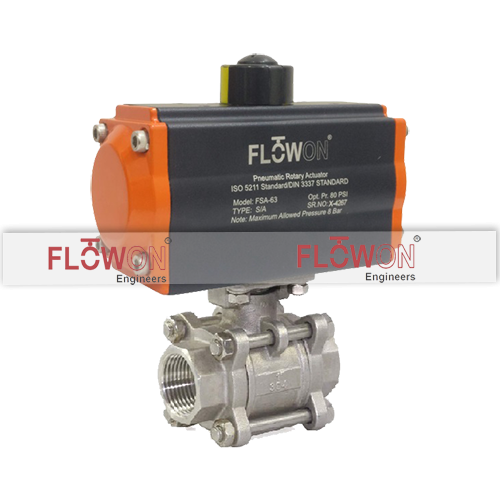

Pneumatic Actuated Ball Valve offered by ‘FLOWON’ helps to automatically control the fluid flow using ‘FLOWON’ pneumatic rotary actuator. ‘FLOWON’ make high quality Investment casted ball valves with ISO 5211 mounting pad are very much suitable for direct mounting of Pneumatic Actuator on Ball Valves. The Actuator used is of Single acting and Double acting depending upon the application. Single acting actuator is used where power fails causes valve to close. On the other hand, Double acting actuator is used where differential pressure on both the supply ports which leads to open and close the valve.

Main components of ball valve include Body, Ball, Seat (PTFE, RPTFE, CFT, Viton etc), Stem, Gland, and Lever. Ball valve is a quarter turn valve which is operated by rotating the ball at its axis to open and close the fluid flow. Ball Valve provides bubble tight shutoff as it uses Soft seat for sealing. Also, the Ball Valve is highly resistant to contaminated media as compared to other valves. ‘FLOWON’ offers Ball valve in 2-Piece and 3- Piece design available in Screwed , Socket and flanged end as per international standards.

KEY FEATURE

- Additional accessories like Solenoid valve, AFR (Air Filter Regulator), Limit switch available upon request.

- Installation of Manual override also available.

- Electro-pneumatic positioner for fully controlling the valve from 0⁰ to 90⁰.

- Direct mounting of actuator on mounting pad ensures easy installation and maintenance.

- Stop pin provided in double acting actuator to limit the travel.

- Low torque values, helps to select small size actuator as compared to other manufacturer valves which reduces cost.

TECHNICAL SPECIFICATIONS & RANGE

ACTUATOR

- Body – AL-Alloy Hard Anodized

- Side Caps – Pressure die casted

- Design – Rack and Pinion type design

- Type – Single Acting / Double Acting

- Mounting Standard – As per ISO 5211

- Connections – As per NAMUR standard

- Operating Pressure – 35 to 150 PSIG

- Operating Temperature – 20⁰C to 80⁰C

VALVE

- Design Standards – B.S 5351 and API 6D standards.

- Testing Standards – B.S 6755 and API 6D standards.

- Body / Ball – Stainless steel, Carbon steel, Cast iron, Alloy steel, Duplex steel etc

- Seat Packing – PTFE, GFT, CFT, Viton, PEEK etc

- End Connection – Screwed End (BSPF, NPTF), Socket Weld End as per 16.11, Flanged End (150#, 300#).

- Design – 2-Piece, 3-Piece design

- Size Range – ½” to 8”

- Pressure Rating Class – 150#, 300#