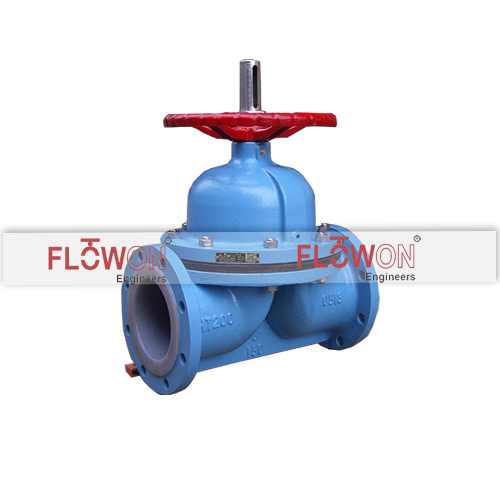

Lined Diaphragm Valve

Lined Diaphragm Valve

‘FLOWON’ make FEP/ PFA/ RUBBER Lined Diaphragm Valve is most commonly used Bi-directional valve in Highly corrosive, abrasive and Slurry applications. Diaphragm Valve are of two types 1) Weir type & 2) Straight type , in which Weir type is mostly used. The name of Diaphragm Valve is due to its thin, flexible Diaphragm used to control the opening and closing of valve. The working function of Diaphragm Valve is attained by linear motion of compressor attached to the Diaphragm. When the hand wheel is open, the compressor moves up and the fluid flows through pipeline & when the hand wheel is closed, the compressor moves down and the fluid stops through pipeline.

SALIENT FEATURES

- Investment wax casted body for high quality finishing.

- Zero porosity due to compact moulding through injection moulded lining.

- The Actuator is not exposed to working media as the high viscous liquid cannot enter to bonnet.

- The maintenance of valve can be done without interrupting pipeline.

- As there are no packing glands, the stem leakage is zero.

- To avoid the friction of spindle with bonnet, Delrin bush is used.

- Stainless steel Spindle is used to avoid corrosion.

PRODUCT RANGE

- Size: – ½” to 10″

MATERIAL SPECIFICATIONS

- Body: – ASTM A 395 Gr. Ductile Iron

ASTM A 216 Gr. WCB

ASTM A 351 GR. CF8 / CF8M - Diaphragm: – PTFE B/W EPDM

- Compressor: – Carbon steel, Stainless Steel

TECHNICAL SPECIFICATIONS

- Design Standard:- BS EN 13397

- Testing Standard:- BS EN 12266-1

Hydrotest:- 16 kg/cm2 (Body) 12 kg/cm2 (Seat)

Air Test :- 6 kg/cm2

Spark Test:- 20 Kv D.C - Drilling Standard:- As per ANSI B 16.5, 150#

- Face to Face Dimensions:- ANSI B 16.10

- Lining Thickness :- 3.0 to 5.0 mm